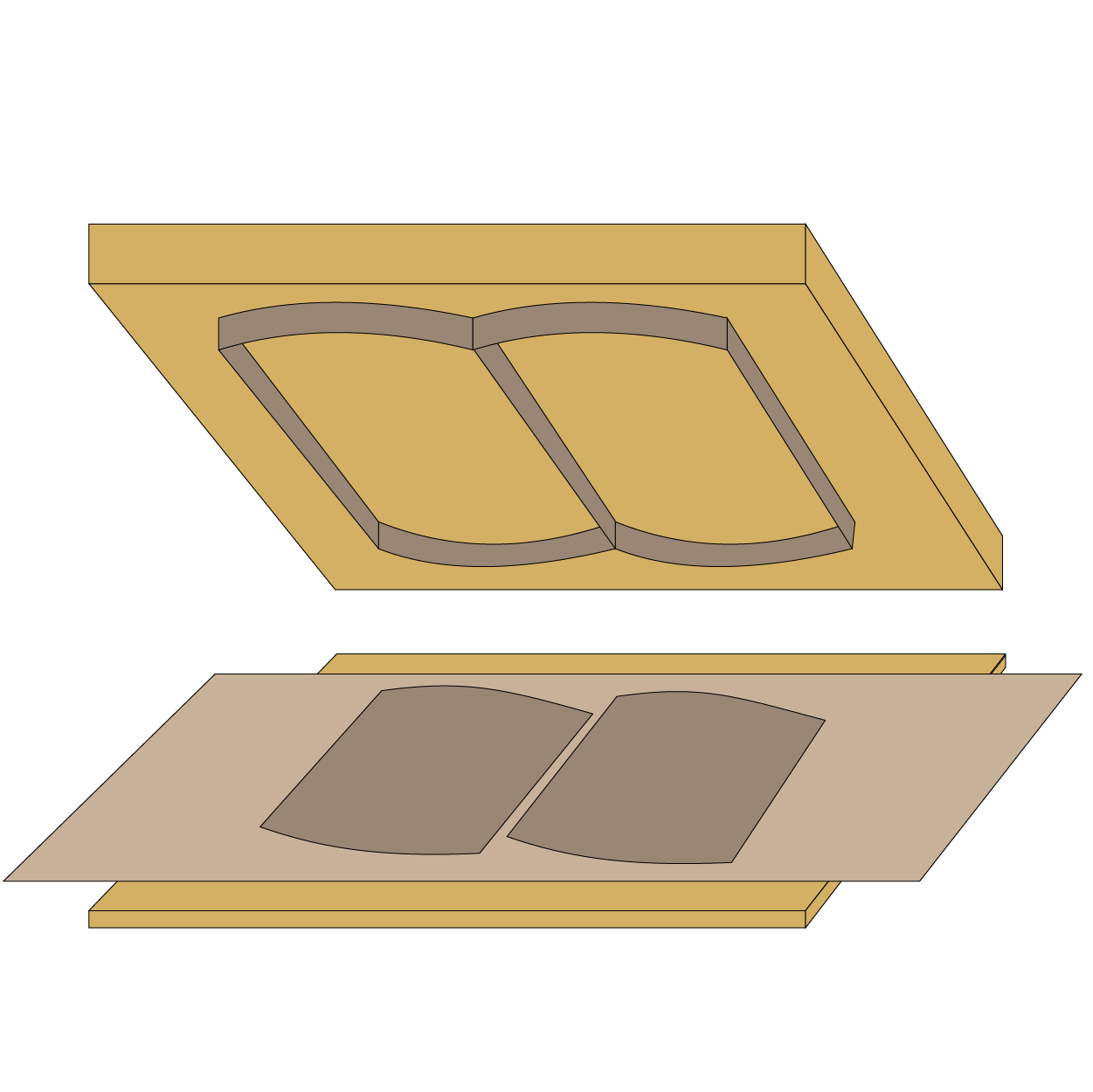

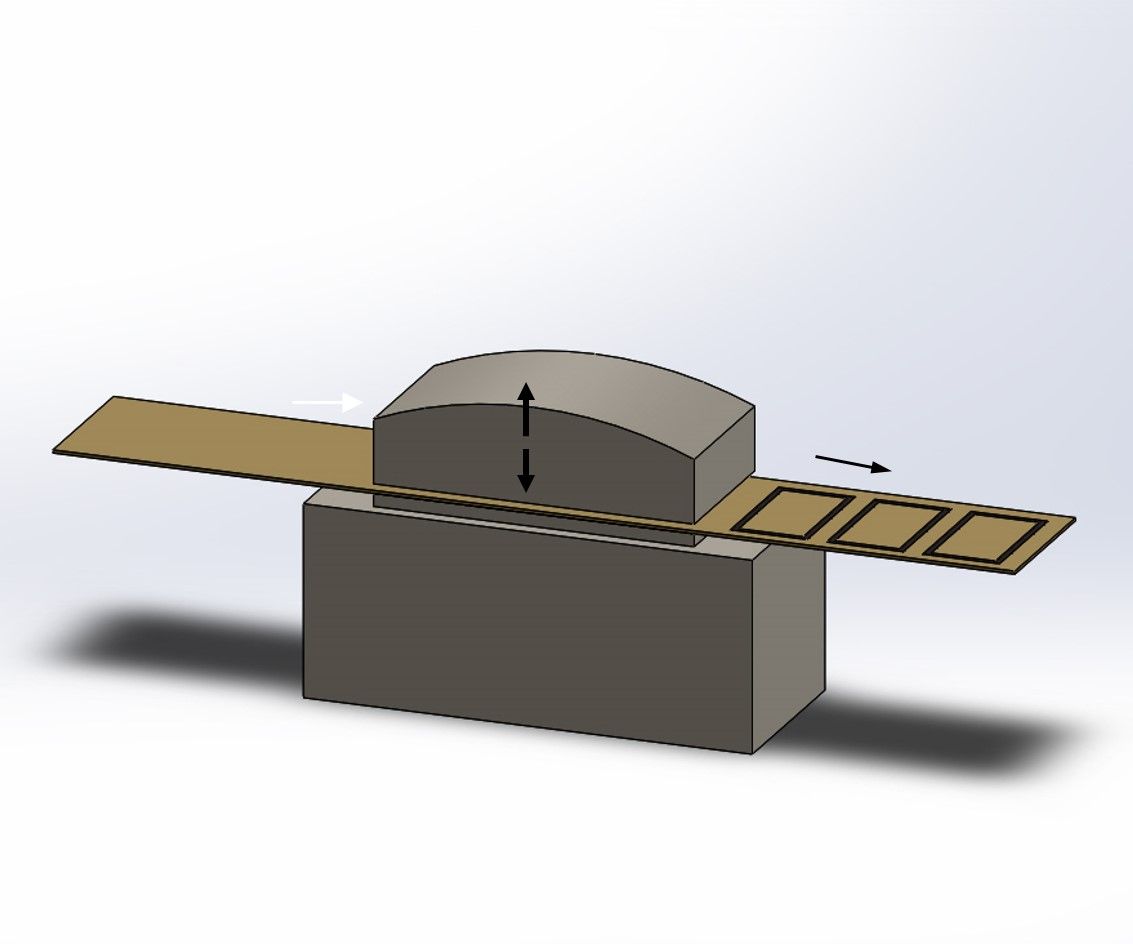

For kiss cutting and die cutting, traditional tools are used. The height of a cutting knife is adjusted according to the type of processing – either die cut (through all) or kiss cut (cutting up to the backing material but not through the liner).

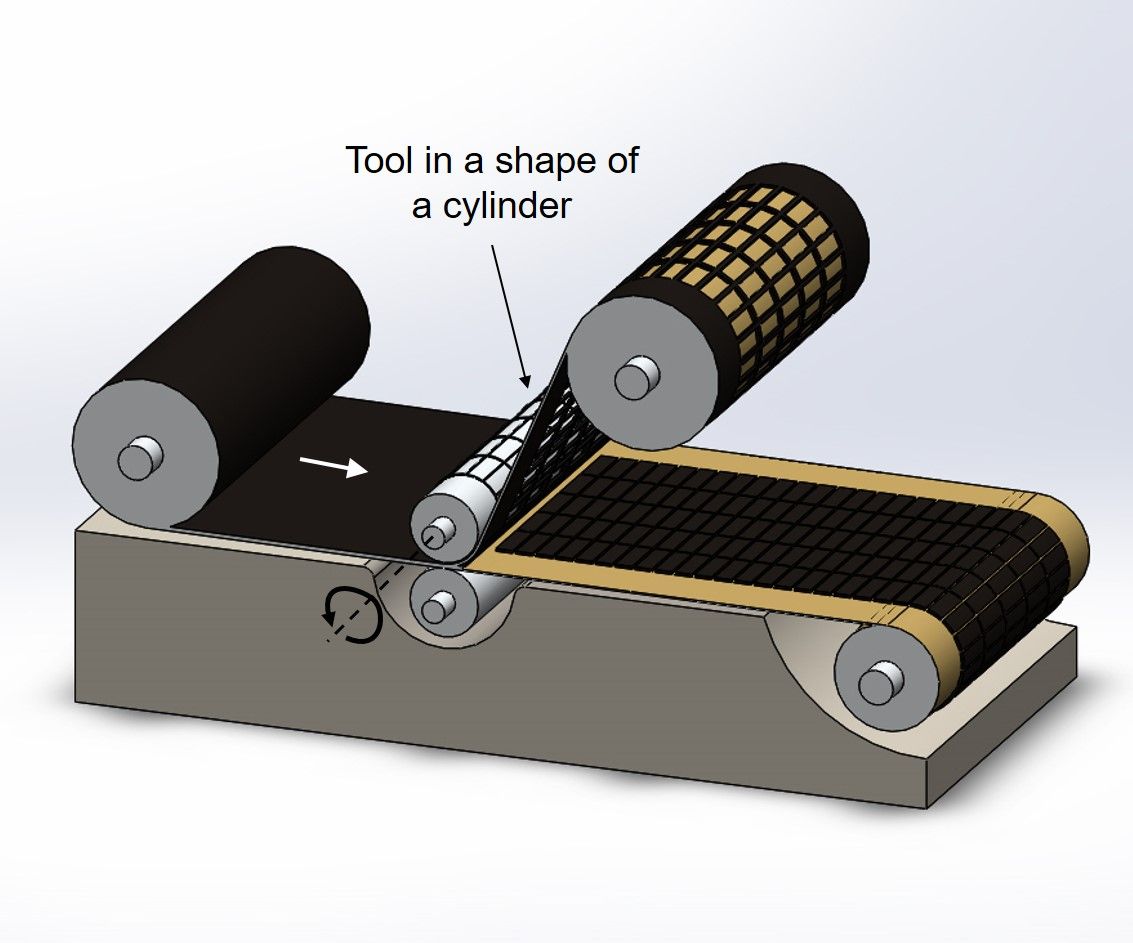

Finished products are available in rolls or cut into any formats and are suitable for machined or hand applications. For better handling and easier application, finger-lifts are frequently shaped. This enables easier removal of a carrier and smooth transfer to a desired surface. Using various machine tools, we can manufacture practically all types of foam materials, adhesive tapes as well as rigid, semi-rigid and soft materials. The principal technologies we employ are flatbed presses (applying a vertically displaced flat tool) and a cylindrical press (utilising a rotary cylindrical tool).

According to the material properties and the customer specific requirements, an array of different techniques and equipment is used. Some of our specialty machines have been designed and manufactured in house to meet any of our customers’ needs. At least 15 years of experience makes us a leading expert in the field of cutting and slitting.

Kiss-cutting

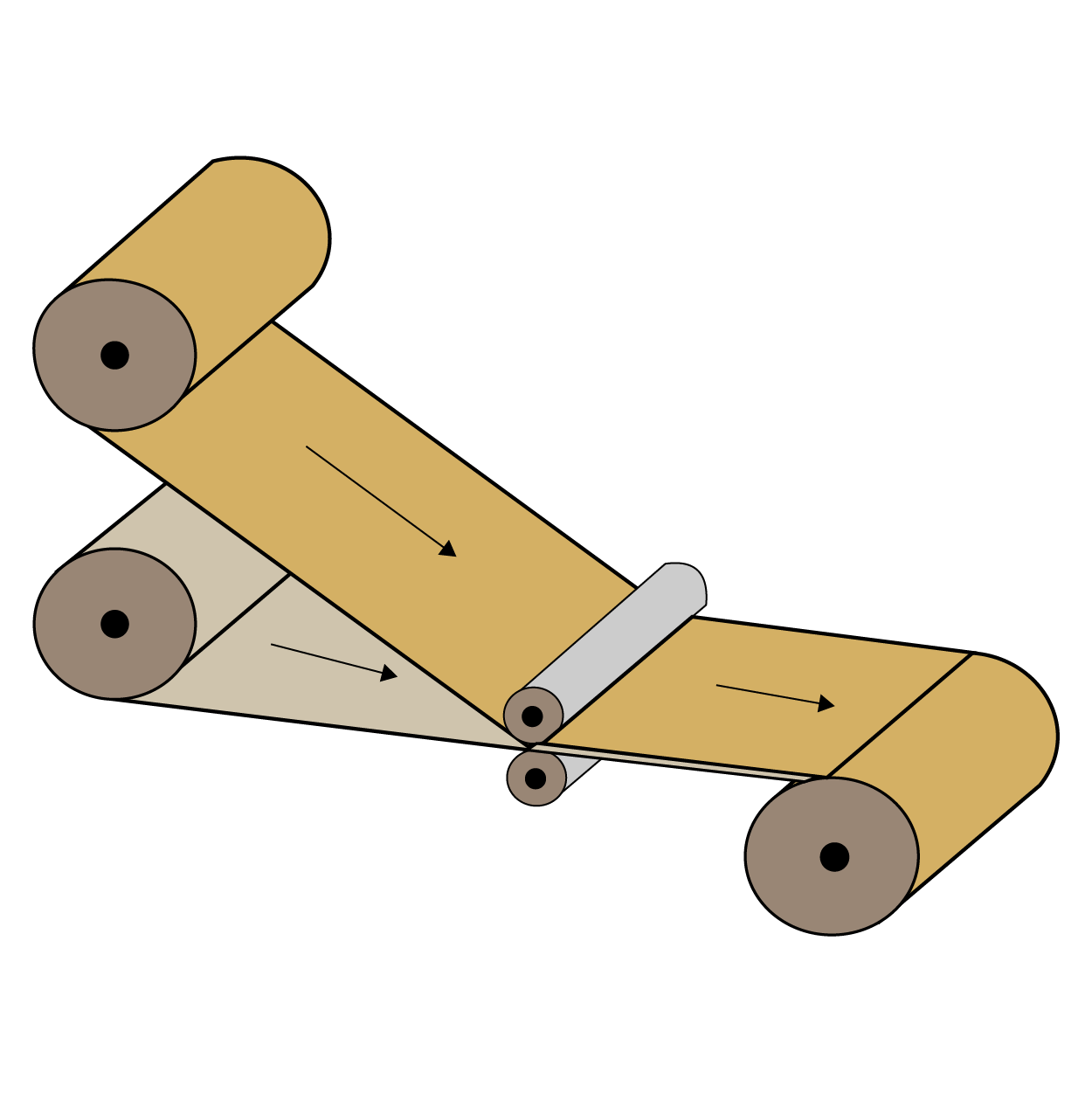

Roll-to-roll kiss cutting is used to cut the top layer of a material without cutting through a backing attached material.

During the kiss cutting process, we employ a flatbed press, utilizing flatbed dies, and a rotary press with a cylinder-shaped tool. This allows the final product to remain on a roll or is cut into any shape or dimension. Not only is it convenient, the kiss-cut method offers a variety of manual and machining applications.

| Tool dimension | 120 x 160 mm | 350 x 500 mm | 300 x 300 mm | Width: 230 mm |

| Max material thickness | 8 mm | 10 mm | 8 mm |

1 mm |

| Materials |

All materials |

All materials |

All materials |

All materials |

Die-cutting

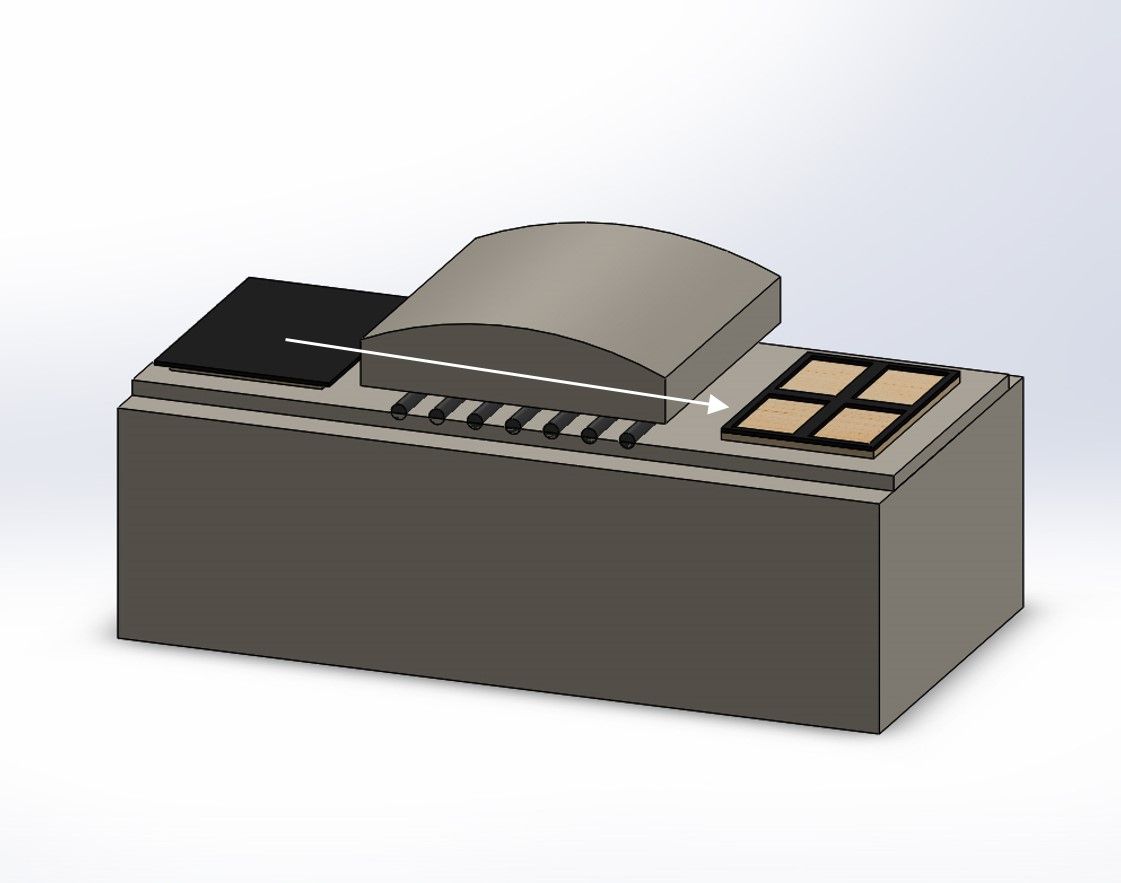

A rotary die-cutting involves using a customized machined part to cut through substrate.

In rotary cutting, a sheet of material is passed through a rolling die and processed by a cylindrical anvil with a customized tool which rolls over a flat surface. This cuts or perforates the desired shape. Rotary die-cutting performs very well in vacuum forming of plastic products. Additionally, it is suited for all adhesion tapes and foam materials supplied in sheets.

| Tool dimension | Width: do 800 mm |

| Max material thickness | Max: 30 mm |

| Max roll weight |

100 kg

|

| Materials | All materials |

TECHNOLOGIES

Anfrage

PLADENT d.o.o.

IBAN: SI0510 0800 0067 019