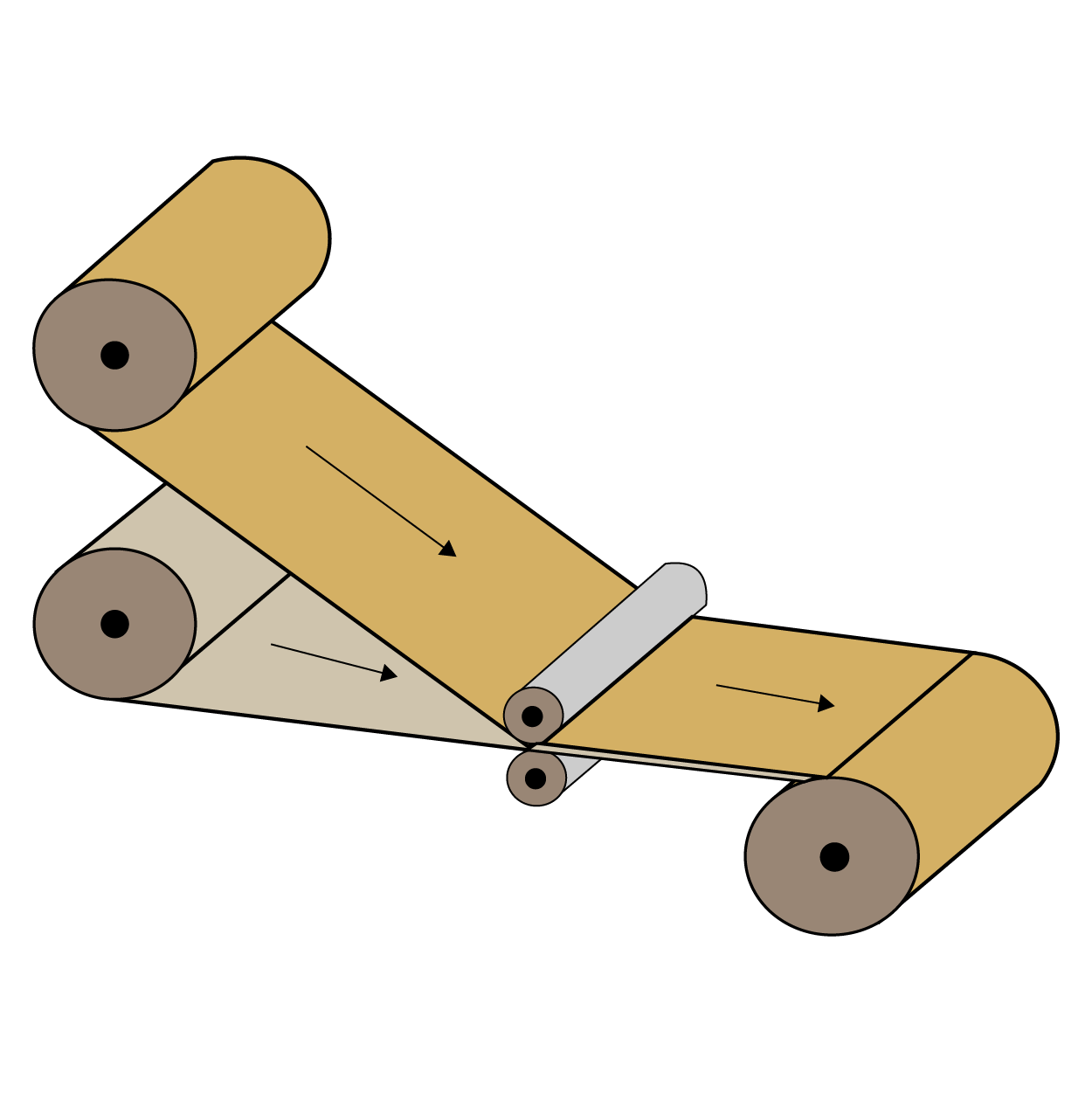

Cutting with an oscillating blade

In an oscillating blade process, the machine features a small, thin sharp blade that is pulled backwards and forwards (oscillates/vibrates) at high speeds and thus slices the material.

The shape of a final product is defined with a pre-loaded digital technical drawing software. This results in a customizable and complex product shape finish.

As the technology is fully automated (computer-driven), it ensures the accurate, clean cutting of foam materials and solid rubber. Oscillating blade machine is suited to many applications and can handle a wide variety of projects. Particularly, we can optimise the process taking into account the small-batches production or sampling, handling materials like EPDM, solid rubber, NBR, neoprene etc., as well as keeping costs down to your best convenience.

| Slitting dimensions | 1200 x 1200 mm |

| Material thickness |

max 50 mm |

| Materials | Foam, solid rubber |

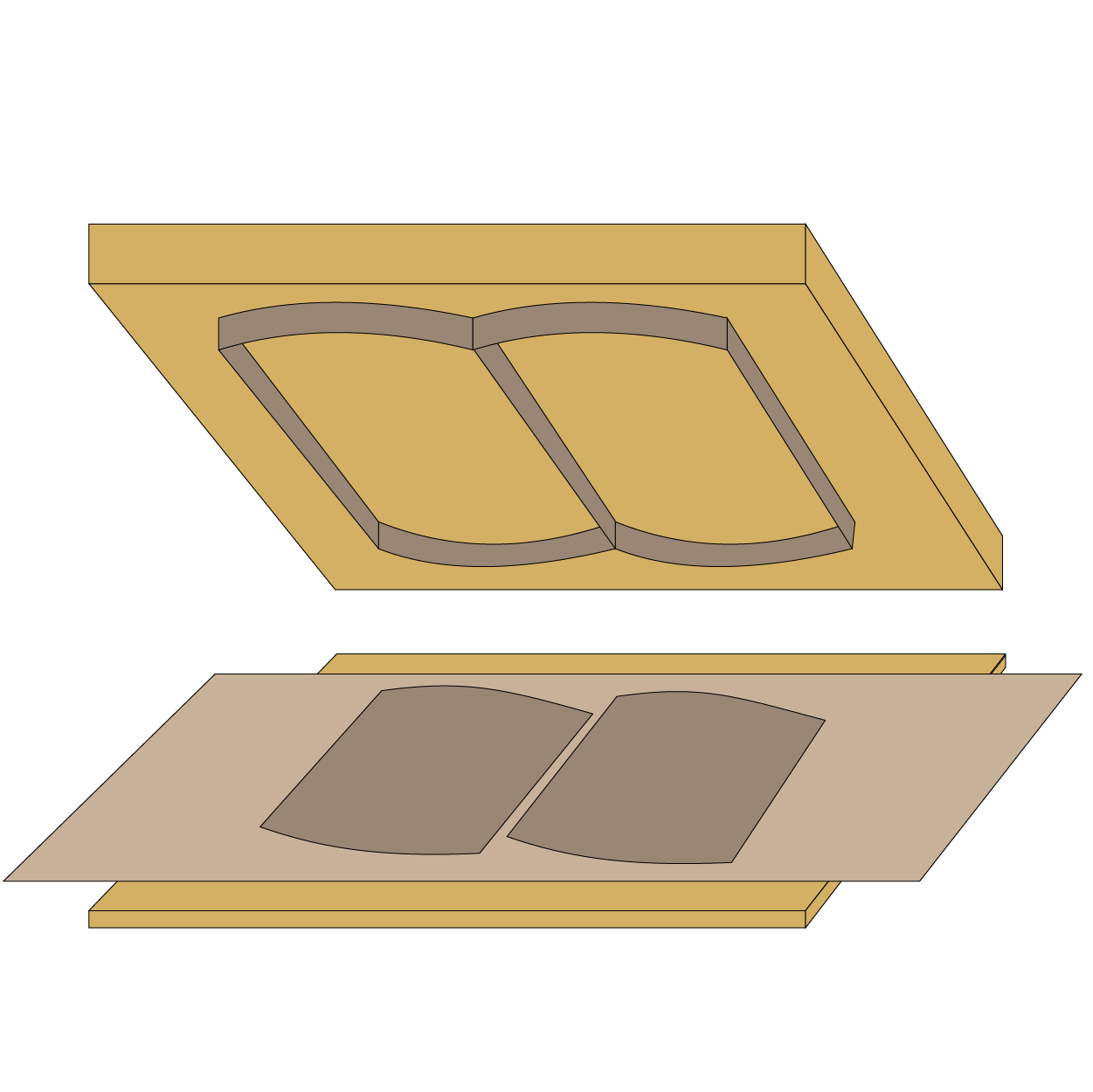

Milling

CNC milling machine is used for manipulating most materials in a very efficient manner. It is used for the shaping of metal and other solid materials such as aluminium, various polymers and foam materials.

The CNC mill is present in products of all types as e.g. aluminium moulds for tools, plastic parts and diverse foam inserts.

| Slitting dimensions | 1200 x 1200 mm |

| Materials | Aluminium, plastics, foam |

TECHNOLOGIES

Anfrage

PLADENT d.o.o.

IBAN: SI0510 0800 0067 019