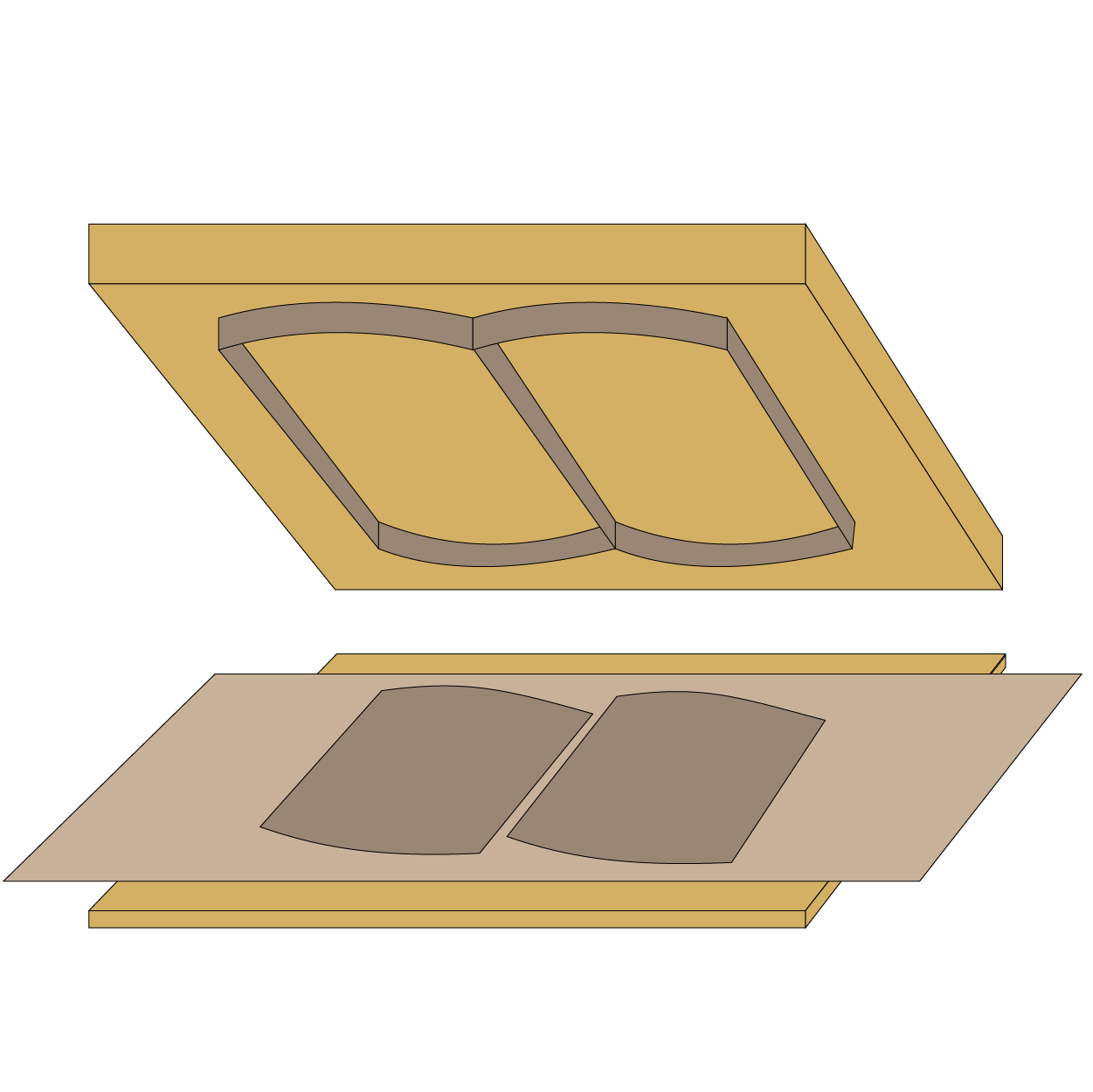

Roll slitting

Two rotary slitting machines are used for slitting soft and semi-rigid materials in rolls (foam, adhesive tapes, felt, etc.).

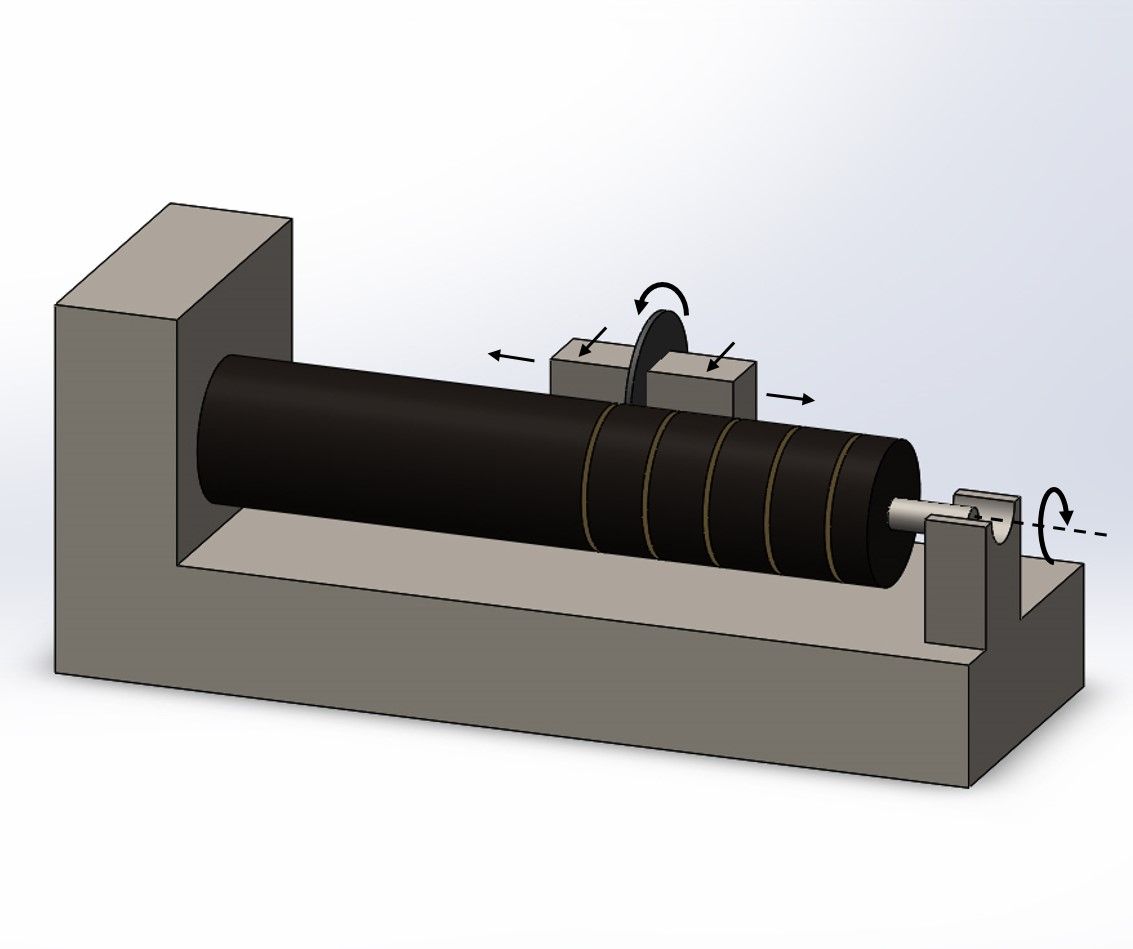

A whole roll of material (a log) is placed into a CNC slitter and then slit into strips by utilizing placement parameters. Minimal slit width primarily depends on a type of material. Compared to rewind slitting, the CNC slitter can achieve higher accuracy of slits.

| Slitting dimensions* |

Min: 4 mm Max: 1500 mm (max roll width) |

| Roll diameter (outer, inner) |

Outer: max. 550 mm Inner: 76 mm (3″) |

| Max roll weight |

100 kg

|

| Materials | Soft and Semi-Rigid Materials, Felt, Foam, Adhesion Tapes, … |

*Slit width depends on a type of material and its properties.

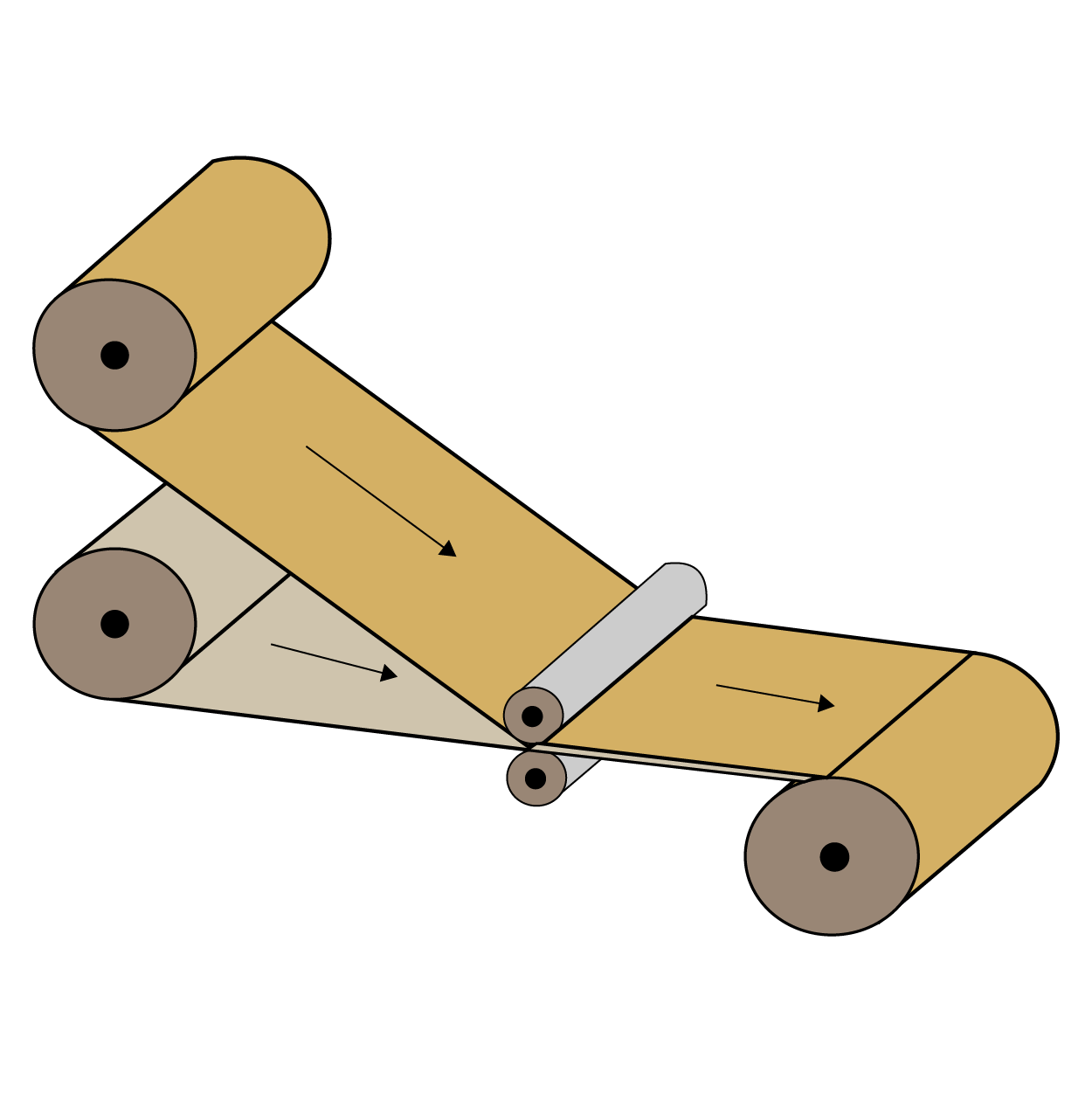

Razor slitting

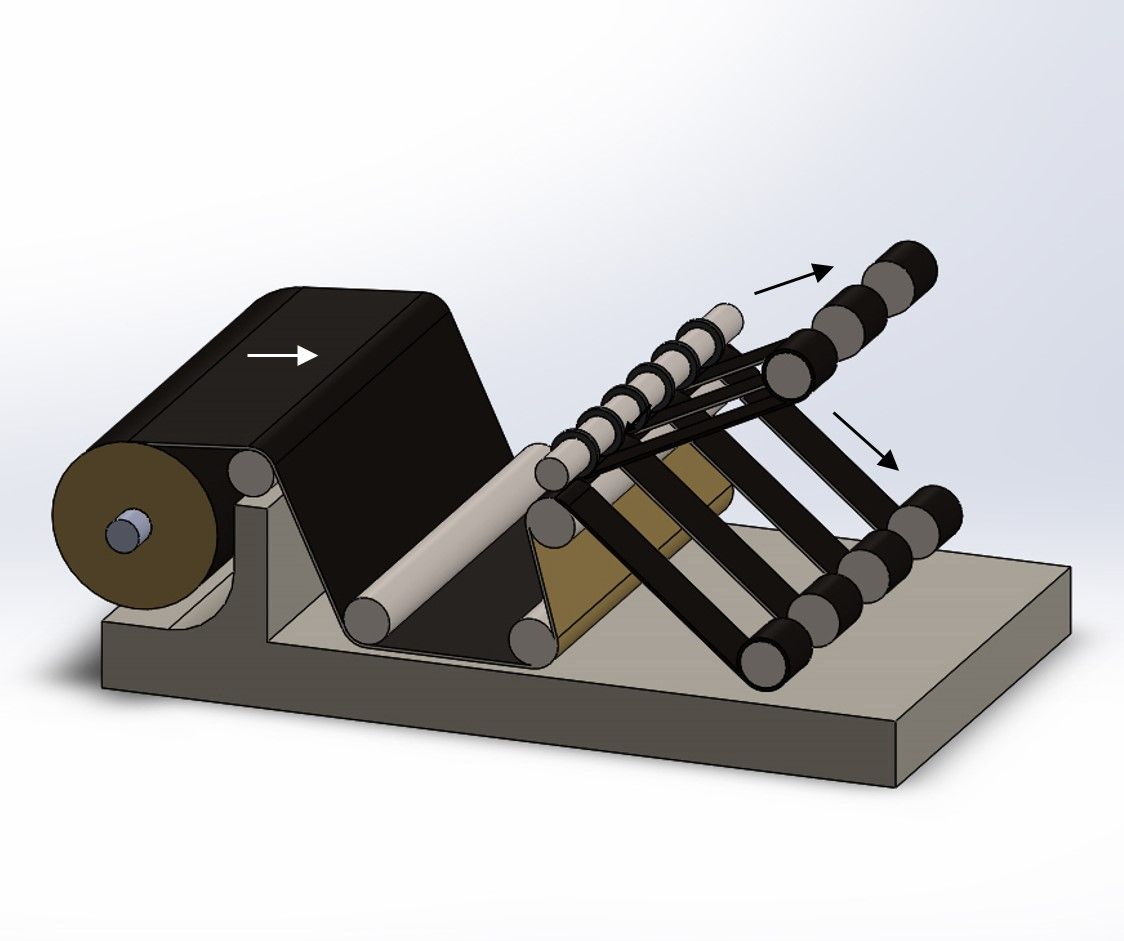

Rewind Slitting is ideal for converting rigid and semi-rigid materials and paper.

In rewind slitting, a whole roll is placed into a slitter rewinder and then passes through a series of blades at a time. The blades are set to customised slit width to form narrower rolls. This type of converting enables relatively quick slitting into rolls of different size and width. However, it has to be noted that the slit tolerances are smaller than with the CNC slitting.

| Slitting dimensions* |

Min: 8 mm Max: 1300 mm |

| Roll diameter (outer, inner) |

Outer: max. 600 mm Inner: 76 mm (3″) |

| Max roll weight |

400 kg

|

| Materials | Rigid, semi-rigid, paper, foil, alufoil, … |

*Slit width depends on a type of material and its properties.

TECHNOLOGIES

Anfrage

PLADENT d.o.o.

IBAN: SI0510 0800 0067 019