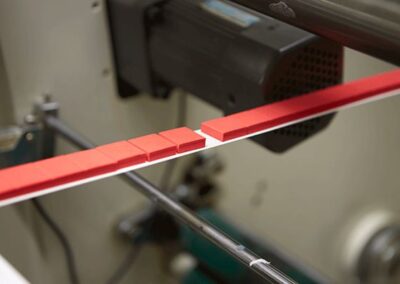

One of our expertise is also cutting and slitting of different types of materials – foams, self adhesives, double sided adhesive tapes, various types of rubber and plastic foils as well as certain fabrics.

According to the material properties and the customer specific requirements, an array of different techniques and equipment is used. Roughly speaking, we deal with three main types of material processings – slitting, die cutting and kiss cutting.

The type and thickness of material determines whether slitting, die cutting or kiss cutting should be employed.

The process of slitting is used to cut a log-roll of material into into a number of narrower coils whereas die cutting is performed to cut out products with the use of cutting blades. In kiss cutting, various tool are used to cut the top layer of a material without cutting through an attached material. In this process, the outline material (usually adhesive-backed foils or papers) of the product can be cut only to particular depth without cutting the release or backing material. In most cases, a combination of cutting techniques is employed. The most appropriate techniques are talked over with customers in advance, with regard to their application needs.

More:

Anfrage

PLADENT d.o.o.

IBAN: SI0510 0800 0067 019